Conveyance Systems for Can Making

Since 1992, Codi has provided conveyance systems to can manufacturing plants in several countries.

We offer a full line of conveyance systems for can making, integrating movement between bodymakers, washers, decorators, neckers, and ovens.

Vacuum Conveyance

Wet & Bright Can System

-

Vacuum Inverter: Transfers cans from the washer, inverting them open-side up for delivery to the base coater or decorator.

-

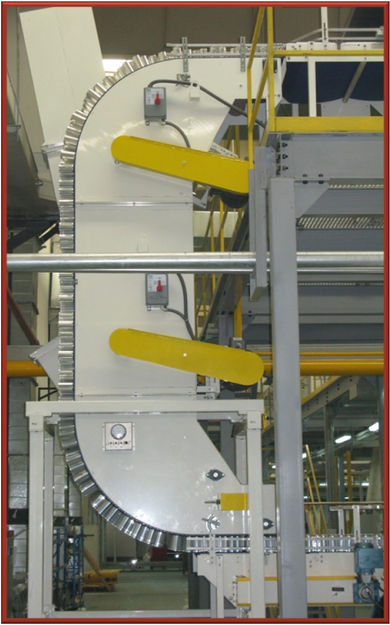

Inverted-S Vacuum Elevator: Lifts cans from the IC spray oven to the mechanical conveyance leading to the necker.

-

Vacuum Transfer: Bridges transitions between mechanical and air conveyance systems.

Single Filers

-

Converging Rail Single Filer: Uses top and bottom air plenums to move cans from a mass flow into a single-file line for feeding the necker.

-

Waterfall Single Filer: Transfers cans from a mass pack through a curved chute, using powered air louvers to align them in single file for the decorators or base coaters.