About Codi

Crafted in the USA, for over 30 years

Jared Jones (right), CEO

Risht

The Codi Way

"As a kid, I saw my parents start the business, I saw the effort, the long hours, the stretching of every dollar. And as a child, I was in it—after school and weekends, helping however I could. So I’ve been ingrained in what became the Codi Way culture from the very beginning.

Those values—we’ll figure it out no matter what—The answer wasn’t, 'no, we can’t.' It was always, 'yeah, we can do that!'"

"Doing it better is our culture. From the start, our retrofit conveyance lines outperformed competitors and were priced more competitively.

In 2015, we built our first automation product — a craft brewery filler made from stainless steel instead of aluminum and designed as a counterpressure system. Everyone thought we were crazy, until they saw a canning line that cleaned easier and filled a wider range of products."

"Doing good work. Deliver what you promise. Stand behind your product. That’s how we’ve built trust — not through ads, but through people. When you treat customers right, they remember you wherever they go.

We don’t play the “better, faster, cheaper” game. Our approach is built on integrity — if it wouldn’t be acceptable to us, it’s not acceptable to ship."

At Codi we do everything above board no sneaky business tactics. You might not always like the answer but you are going to get it straight, with no b.s.

"Today we own the controls and line logic, delivering complete systems — not just pieces. We keep innovating by listening to customers and solving real problems with the latest technology. While others stick to “if it ain’t broke, don’t fix it,” we design to add value. This is the digital industrial age, and we’re here to win it — with high expectations and a sense of fun."

Codi Machinery

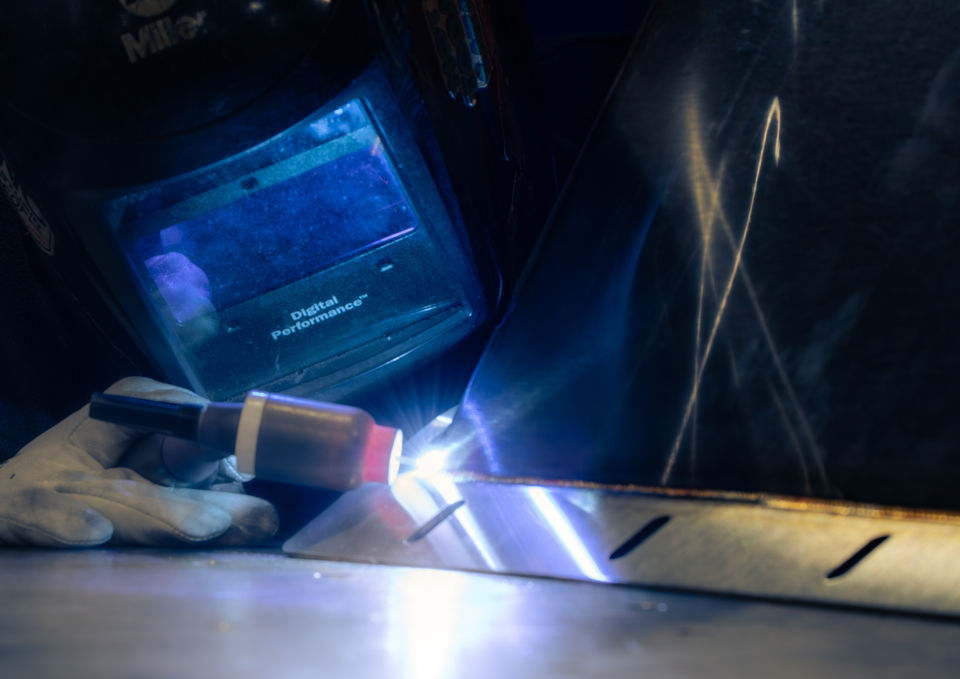

Precision Design

Metalwork Refined

Hex forms add build time, but they strengthen the structure, improve tolerance and provide pathways for cable routing.

We’ve perfected our bend deductions, so parts nest and tab together perfectly.

Codi Machinery Pics by Cody Vance

Codi Patents

Codi holds multiple U.S. patents across filling, seaming, cleaning, and conveying systems.

Filling & Seaming

Patented counterpressure control using modulated pinch valves enables infinite fill and snift setpoints via HMI—adapting to varying carbonation, temperature, and product types. Our continuous-motion, position-controlled seamer achieves up to 65 CPM with consistent seam quality and reduced dissolved oxygen through synchronized LN₂ dosing.

Cleaning Systems

The Loop Rinser patent utilizes a vacuum conveyor to invert and rinse cans with ionized air, eliminating twist rinses and reducing changeover time for multi-size lines.

Conveyance Conversions

Codi’s conveyor retrofit patents replace rollers with modular plastic belts—reducing noise, wear, and container damage while simplifying maintenance.

Add paragraph text. Click “Edit Text” to update the font, size and more. To change and reuse text themes, go to Site Styles.

Codi is Veteran-Owned

& Crafted in Colorado

7910 Shaffer Pkwy

Littleton, Co 80127

© 2025 Codi Manufacturing