Container Cleaning

Gripper/Wedge Rinser

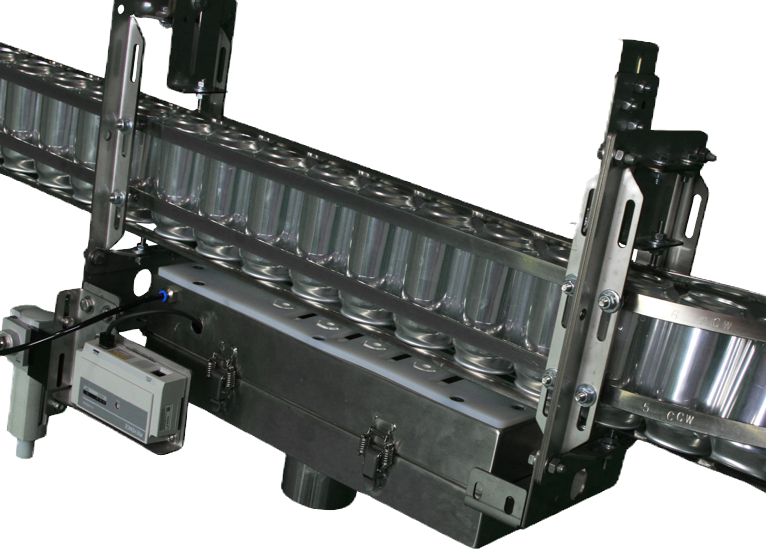

The gripper rinser (also known as a wedge or "Lowerator") grips each container between opposing belts, opening the container for full 360-degree access during rinsing or cleaning. By elevating and inverting the product in a controlled path, it ensures consistent exposure to spray nozzles while maintaining gentle handling.

Twist Rinser

The Twist Rinse inverts empty cans for rinsing with ionized air, sanitizer, or water before returning them upright to the filler. Built with commercial-grade 5/8" half-round stainless steel for stable container transfer. Multiple units can mount to a depalletizer for rapid changeovers between can sizes.

Vacuum Loop Rinser

The Vacuum Loop Rinser uses suction to move any size container from Depalletizer to Filler. Empty cans or aluminum bottles are supplied to the Vacuum Rinser from an overhead single lane conveyor. The cans are inverted via a patented “Loop” configuration where they optionally pass over an Ionized Air Rinser for pre-fill can cleaning.

Vacuum S-Rinser

The Vacuum S-Rinser uses suction to move any size container from Depalletizer to Filler. Empty cans or bottles are supplied to the Vacuum Rinser from an overhead single lane conveyor. The cans are inverted via a patented “S” configuration where they optionally pass over an Ionized Air Rinser for pre-fill can cleaning.

_edited.jpg)

.png)