Conveyors for Can Making

Since 1992, Codi has provided conveyance systems to can manufacturing plants in several countries. We design and build integrated systems that support speed, precision, and long-term reliability for manufacturers operating in demanding production environments. In fact, many systems we designed and installed 30 years ago are still in use! Our expertise lies in creating equipment that fits seamlessly into high-output can-making processes, from rinsing to filling and downstream handling.

Our conveyance systems for 2-piece can making efficiently transport, align, and space cans while maintaining hygiene standards throughout the line. These systems enable consistent production rates and minimize downtime.

We offer a full line of conveyance systems for can making, integrating movement between bodymakers, washers, decorators, neckers, and ovens. See below for a sample of our offerings.

Vacuum Conveyance

Wet & Bright Can System

-

Vacuum Inverter: Transfers cans from the washer, inverting them open-side up for delivery to the base coater or decorator.

-

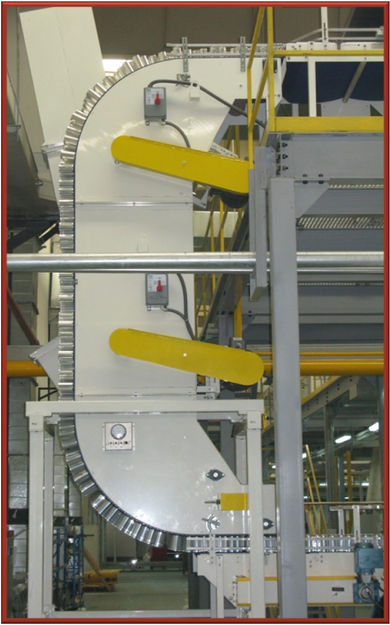

Inverted-S Vacuum Elevator: Lifts cans from the IC spray oven to the mechanical conveyance leading to the necker.

-

Vacuum Transfer: Bridges transitions between mechanical and air conveyance systems.

Single Filers

-

Converging Rail Single Filer: Uses top and bottom air plenums to move cans from a mass flow into a single-file line for feeding the necker.

-

Waterfall Single Filer: Transfers cans from a mass pack through a curved chute, using powered air louvers to align them in single file for the decorators or base coaters.

Custom Solutions

Designed Around Your Facility

Codi Manufacturing engages with our customers to understand the unique characteristics of their facility to design material handling solutions to be compatible with the upstream and downstream equipment.

The material handling and automation capabilities of Codi are:

-

Drop in replacement conveyor systems and conveyors for cans, packages and finished products.

-

Automated product filling, packaging and post-fill processes.

-

Space-based, speed-based, and safety-based layout-driven engineering.

-

Combined with canning, labelling, and packaging machines.

-

Plans that minimize handwork and operational bottlenecks.

All systems are built in our Colorado facility and, according to the Codi Way, are designed by us to be easy to service and to last for decades.

Built for Generations,

Supported for the Long Term

For us, our relationship with our customers does not end at installation. We are here for our customers for the long run to provide spare parts, knowledgeable and available service representatives, and product tutorials.

Through the incorporation of Material Handling Systems into the larger packaging line design, Codi will reduce downtimes, enhance the efficiency of the working process and ensure the safety of the production conditions.

Contact Codi today to discuss your facility requirements and discover how custom-engineered material handling and automation solutions can support your operation now and in the future.